What are the components of pyrite sand? A detailed explanation of its constituent elements and application value

Release time: 2025-12-08

Table of Contents

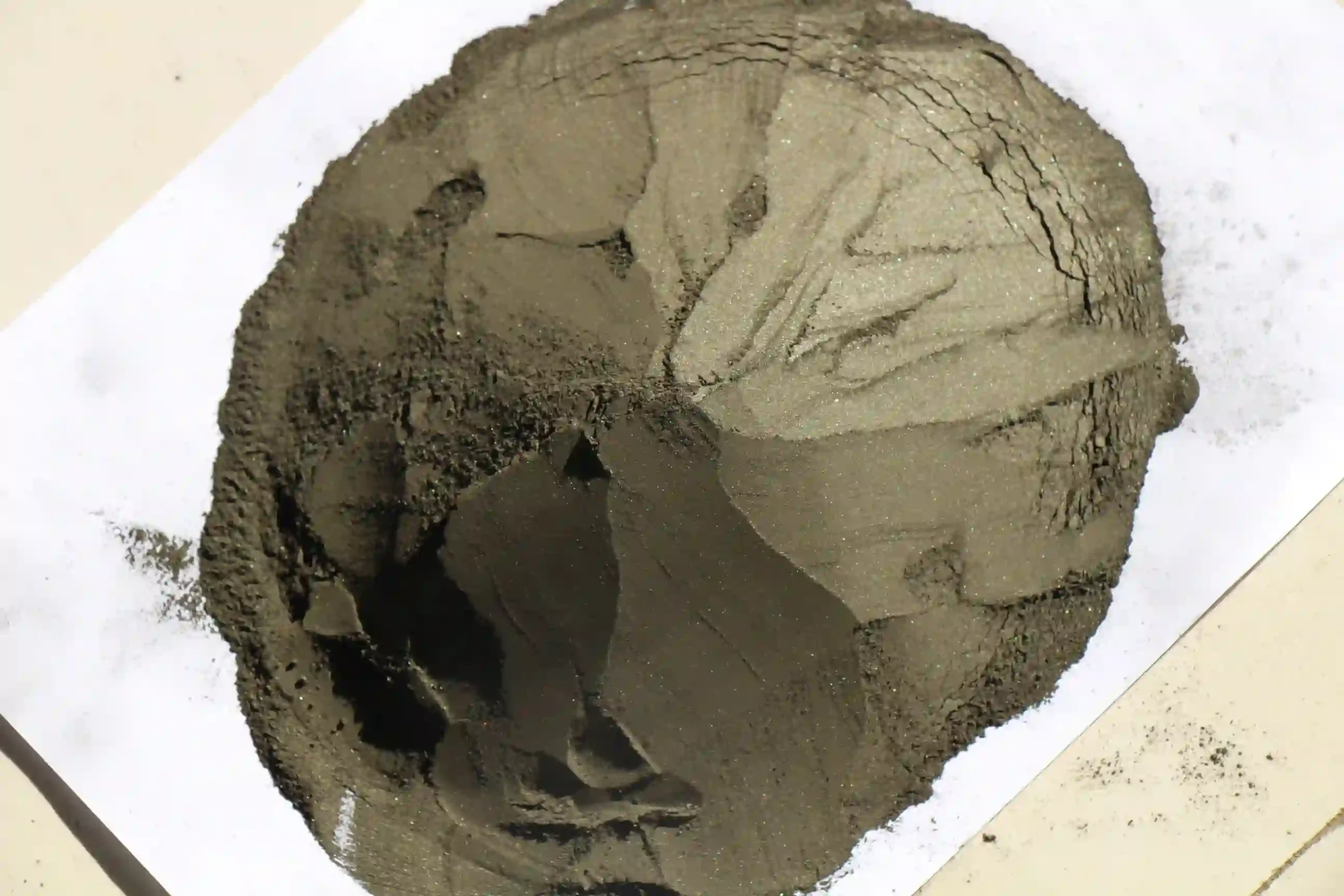

Pyrite sand is a common sulfide mineral with the chemical formula FeS₂, also known as “fool’s gold” due to its golden metallic luster. With the continuous expansion of industrial demand, the use of pyrite sand in metallurgy, friction materials, casting, and chemical industries is gradually increasing. To help buyers and manufacturers better understand its quality indicators, we will provide a detailed introduction to the main components and functions of pyrite sand, covering its composition, impurity content, and industrial applications.

What are the core components of pyrite sand?

The main chemical components of pyrite sand are iron (Fe) and sulfur (S). Its structure is composed of iron disulfide, with a sulfur content typically ranging from 46% to 48%, and an iron content of approximately 42% to 47%. High-grade pyrite sand has a more stable sulfur content, which is beneficial for its use as a sulfur or iron source additive in industrial production, ensuring the accuracy of the reaction process and the stability of product performance.

Different mining areas and processing methods can lead to variations in composition; therefore, it is crucial to pay close attention to the sulfur content, iron content, and impurity ratio during procurement. These are important indicators for evaluating the quality of pyrite.

Common impurities and their effects

In addition to iron and sulfur, pyrite sand may also contain small amounts of quartz, calcite, oxides, and other metal element impurities. The lower the impurity content, the closer its performance is to high-purity pyrite powder or pyrite sand standards, and the more stable its performance in the metallurgical and friction material industries.

Common impurities include:

Silicon dioxide (SiO₂)

Trace amounts of metals such as lead, copper, and zinc

Small amounts of carbon and moisture

When the impurity content is low, pyrite sand is easier to control during the reaction process, making it particularly suitable for companies requiring stable formulations, such as those in the brake pad, friction material, and casting additive industries.

Industrial application value of pyrite sand

Due to its reliable performance, high sulfur content, and strong temperature resistance, pyrite sand is widely used in various industrial applications. High-temperature resistant pyrite sand performs particularly well in the friction materials industry, improving the stability of products in high-temperature friction environments, preventing decomposition, and increasing product strength and lifespan. Its main applications include:

Friction materials: brake pads, clutches, brake blocks, etc.

Metallurgy: as a flux or sulfur raw material additive

Casting industry: improving metal fluidity and surface finish

Chemical production: used in sulfuric acid and other sulfur-containing synthetic raw materials

Agricultural soil conditioning: as a sulfur nutrient supplement

Due to its wide range of uses, different fields have different requirements for particle size, sulfur content, and moisture content. Fine pyrite powder, pyrite sand, or high-purity grade products can be selected to suit specific needs.

How to choose high-quality pyrite sand?

When purchasing, you can evaluate the following indicators:

Is the sulfur and iron content stable?

Is the impurity ratio low and does it meet industrial standards?

Is the particle size distribution uniform?

Are test reports and technical parameters available?

Does it support sample testing and customized specifications?

Stable raw materials can effectively reduce production costs and improve product consistency.

Conclusion

Pyrite sand is mainly composed of iron and sulfur, and has high activity and temperature resistance advantages in industrial fields, making it an indispensable basic raw material for metallurgy, friction materials, and chemical industries. Understanding the composition and impurity ratio of pyrite sand helps companies choose more suitable materials, improving production efficiency and product quality.

If you are looking for high-purity pyrite powder or high-temperature resistant pyrite sand, please contact Tongling Bainuo to obtain specifications, test data, or samples. We can provide customized pyrite sand solutions based on different applications.