The Storm of Grinding Wheel Manufacturing Materials: Can the “throne” of pyrite be shaken?

Release time: 2025-10-23

1.The Role of pyrite in Grinding Wheel Manufacturing Revealed

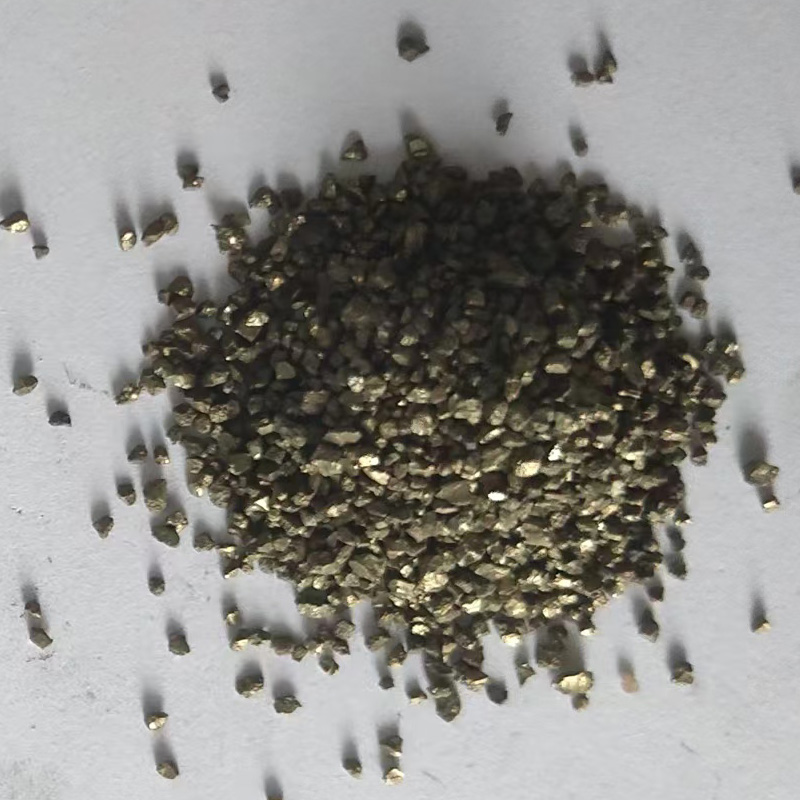

In the complex process system of grinding wheel manufacturing, pyrite plays a crucial role as a filler, contributing significantly to the optimization of grinding wheel performance. From a physical perspective, pyrite, whose main component is iron disulfide (FeS₂), endows grinding wheels with a series of excellent properties due to its unique chemical composition and structure.

During the grinding process, the grinding wheel and the material being processed undergo intense friction, generating a large amount of heat. Excessively high temperatures not only reduce the grinding efficiency of the grinding wheel but also may lead to accelerated wear of the grinding wheel, deterioration of the surface quality of the processed material, and even burning. The addition of pyrite can effectively lower the grinding temperature. This is because pyrite undergoes chemical reactions at certain temperatures, absorbing some of the heat and thus playing a role in heat dissipation. Relevant research data indicates that when grinding with grinding wheels containing pyrite, the temperature in the grinding area can be reduced by 20% to 30%, significantly improving the grinding environment.

Pyrite can also significantly enhance the heat dissipation of the grinding wheel. Its special crystal structure and thermal conductivity enable heat to be conducted away from the grinding area more rapidly, preventing heat from accumulating locally in the grinding wheel. This not only helps maintain the structural stability of the grinding wheel but also reduces problems such as grinding wheel cracking caused by thermal stress, thereby extending the service life of the grinding wheel. Practical application cases show that the service life of grinding wheels with added pyrite can be extended by 1 to 2 times compared to those without.

In the field of rail grinding, the performance of the grinding wheel directly affects the maintenance quality and service life of the rails. For instance, in a certain railway maintenance project, the proportion of pyrite used in the rail grinding wheels was 15% to 20%. In long-term actual grinding operations, these grinding wheels demonstrated outstanding performance. They could effectively grind the rail surface, removing wear, cracks, and other defects. Moreover, due to the effect of pyrite, the grinding wheels maintained good stability in high-temperature and high-pressure grinding environments, with a low wear rate, significantly reducing the frequency of grinding wheel replacement, improving the efficiency and economy of grinding operations, and ensuring the safe operation of railways.

2.A comprehensive review of potential alternative materials

With the continuous advancement and development of materials science, to meet the demands of the grinding wheel manufacturing industry for high-performance, environmental protection, and sustainable development, numerous researchers and enterprises are actively exploring new materials that can replace iron sulfide ore. After continuous research and practice, several potential materials have been discovered, which demonstrate unique performance advantages in the field of grinding wheel manufacturing.

Thermosetting phenolic resin powder: As a high-molecular material, thermosetting phenolic resin powder has excellent heat resistance and stability. In grinding wheel manufacturing, it can work synergistically with other raw materials to significantly enhance the rotational strength of the grinding wheel. Its unique chemical structure forms a solid three-dimensional network after curing, effectively enhancing the overall strength of the grinding wheel, ensuring its stability during high-speed rotation and grinding, and reducing the risk of cracking.

Carbon-containing resin powder: The carbon-containing resin powder contains a high carbon residue content. During the curing process, it can form a carbon bonding network, which significantly improves the sharpness of the grinding wheel. The potential replacement material, the carbon bonding network, is like countless tiny cutting edges, enabling more effective penetration into the processed material during grinding, thereby improving grinding efficiency and enhancing the bonding strength between raw materials, prolonging the service life of the grinding wheel.

Special ceramic powders: Special ceramic powders such as alumina ceramic powder and silicon carbide ceramic powder have high hardness, high wear resistance, and good chemical stability. Their hardness is usually higher than iron sulfide, providing stronger grinding capabilities and being suitable for processing materials with higher hardness. Moreover, the chemical stability of ceramic powders ensures that they do not undergo chemical reactions in harsh grinding environments, maintaining the durability of the grinding wheel performance.

3.Comprehensive Evaluation and Future Outlook

When considering various factors such as comprehensive performance and cost, pyrite has unique cost advantages in grinding wheel manufacturing. Its low procurement cost and simple processing technology make grinding wheels filled with pyrite more competitive in terms of price. This is an important factor that cannot be ignored in the cost-sensitive mid-to-low-end grinding wheel market. However, in terms of performance, potential replacement materials such as thermosetting phenolic resin powder, carbon-containing resin powder, and special ceramic powder have shown significant advantages. They outperform pyrite in key performance indicators such as grinding efficiency, grinding wheel lifespan, impact on metal surfaces, and chemical stability, and can better meet the strict requirements for high-performance grinding wheels in the high-end grinding field.

Therefore, whether pyrite can be replaced in grinding wheel manufacturing cannot be generalized. It depends on the specific application scenarios and requirements. In the mid-to-low-end grinding wheel market, due to cost being the main consideration factor, pyrite will still occupy a certain market share in the short term. However, in the long run, as materials science continues to progress and the market’s requirements for grinding wheel performance increase, especially in the booming trend of high-end manufacturing, these more superior potential replacement materials will gradually emerge in the high-end grinding wheel manufacturing field and gain wider application.

Looking ahead, the development direction of grinding wheel manufacturing materials will focus on the research and development of more environmentally friendly, high-performance, and cost-effective materials. On one hand, the research and development of environmentally friendly materials will become the focus to meet increasingly strict environmental regulations and sustainable development requirements. For example, the research on recyclable, low-pollution matrix materials and abrasive will help reduce the environmental impact of grinding wheel manufacturing and use. On the other hand, through material innovation and process optimization, further improve the performance of grinding wheels, such as increasing grinding accuracy, enhancing wear resistance and heat resistance, while reducing production costs, achieving the best balance between performance and cost, is an important goal for the development of grinding wheel manufacturing materials in the future. Additionally, with the rapid development of intelligent manufacturing and high-end equipment manufacturing, grinding wheel manufacturing materials need to continuously adapt to the special requirements of emerging application fields, such as the high precision and reliability requirements of sanders for the automotive industry, semiconductor, and medical devices, to provide strong support for the development of these industries.