エネルギー貯蔵の未来:黄鉄鉱粉末がリチウムイオン電池の次なるゲームチェンジャーとなる理由

Release time: 2026-02-04

If you’ve been following the EV (electric vehicle) and renewable energy sectors lately, you know the industry is facing a massive bottleneck: materials.

We are digging deeper for lithium and scrambling for cobalt, driving costs up and creating supply chain nightmares. But while the world fights over rare earth metals, a quiet revolution is happening in the labs of top battery manufacturers. They are turning their attention to a material that has been around forever, often dismissed as “fool’s gold.”

I’m talking about 黄鉄鉱粉末 (iron disulfide, or FeS₂).

And if you are in the business of energy storage or material sourcing, you need to pay attention. Here is why this humble mineral is poised to be the next big thing in the lithium-ion landscape.

The Density Dilemma: Why We Need a Switch

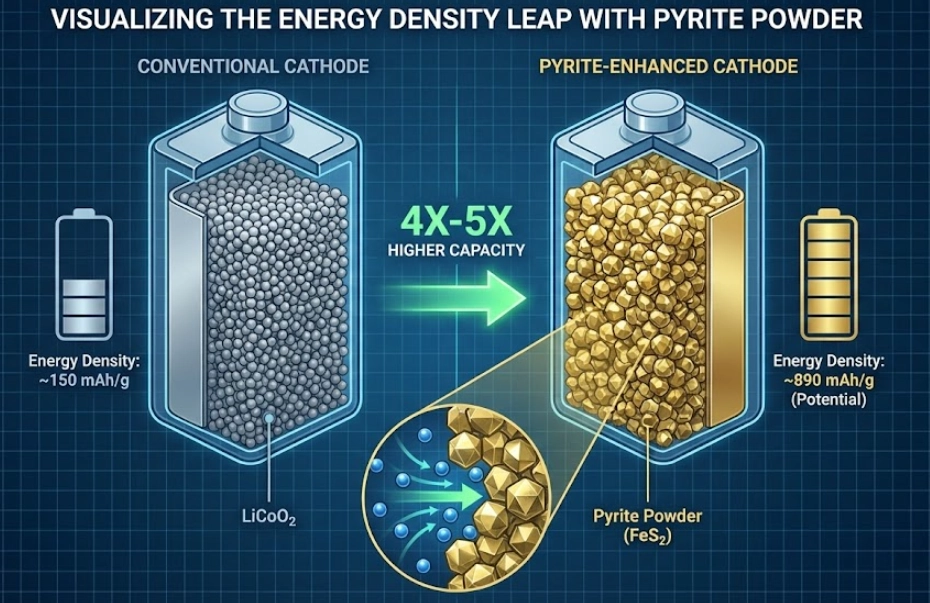

Let’s get technical for a second—but keep it simple. The current standard for battery cathodes (like lithium cobalt oxide) has pretty much hit its theoretical limit. We are squeezing every last drop of juice out of them, but we need more range for cars and longer life for devices.

This is where 黄鉄鉱粉末 enters the chat.

Theoretically, iron disulfide ($FeS_2$) has a specific capacity of around 890 mAh/g. To put that in perspective, that is roughly four to five times higher than the conventional cathode materials we use today.

Imagine an EV that drives 800 miles on a single charge instead of 300, without making the battery pack physically larger. That isn’t science fiction; it’s the potential of pyrite-based chemistry. By integrating high-purity pyrite powder into the cathode mix, researchers are unlocking energy densities that were previously thought impossible at a commercial scale.

The Economic Advantage: It’s Dirt Cheap (Literally)

The biggest problem with the current battery supply chain? It’s expensive and geopolitically fragile. Cobalt mining, for instance, is fraught with ethical and logistical issues.

Pyrite, on the other hand, is abundant. It is one of the most common sulfide minerals on Earth.

For manufacturers, switching to or incorporating 黄鉄鉱粉末 means escaping the volatility of the rare metal market. It offers a stable, low-cost raw material supply chain. When you are producing millions of battery cells, reducing the cost of the cathode material by even 10% is a massive win. Pyrite offers savings far greater than that.

It’s Greener Than You Think

We talk a lot about “green energy,” but the production of current batteries is often anything but. Extracting nickel and cobalt is energy-intensive and dirty.

Pyrite is naturally occurring and requires significantly less processing energy to refine into a usable industrial powder compared to synthetic metal oxides. Furthermore, iron and sulfur are non-toxic and environmentally benign compared to heavy metals like cobalt.

For companies looking to improve their ESG (Environmental, Social, and Governance) scores, sourcing high-quality pyrite powder is a step toward a truly sustainable battery lifecycle.

The Challenge: Why Quality Matters More Than Ever

Now, I know what you’re thinking. “If Pyrite is so great, why aren’t all Teslas running on it yet?”

There have been historical hurdles. In the past, using iron disulfide in rechargeable batteries led to volume expansion issues during cycling (the battery would physically swell and degrade).

However, in 2026, material science has evolved. The solution lies in particle engineering.

It is no longer enough to just dig up a rock and crush it. The modern battery industry requires 黄鉄鉱粉末 with:

- High Purity: Impurities like silica or lead can ruin battery chemistry. You need FeS₂ content typically above 95% or 98%.

- Optimized Particle Size: We are seeing a shift towards ultra-fine meshes (like 325 mesh or even nano-scale milling). Smaller, uniform particles accommodate the volume changes better and improve the conductivity of the cathode.

This is where sourcing becomes critical. You can’t just buy generic “ore” for these applications. You need processed, industrial-grade powder designed for chemical stability.

The Verdict

We are standing on the edge of a new era in energy storage. While solid-state batteries get the flashy headlines, the optimization of lithium-sulfur and lithium-iron-sulfide chemistries is where the immediate, scalable breakthroughs are happening.

Pyrite powder is no longer just a commodity for grinding wheels or glassmaking. It is becoming a strategic energy material.

For procurement managers and R&D teams, the message is clear: the companies that secure high-quality, consistent supplies of iron disulfide now will be the ones leading the pack when the next generation of batteries hits the mass market.

Don’t let the nickname “Fool’s Gold” fool you. In the battery world, this stuff is the real deal.

Looking for premium-grade FeS₂?

At TLB, we specialize in processing high-purity industrial minerals. Whether you are researching battery cathodes or manufacturing high-performance friction materials, we have the specifications you need.