For concrete surface profiling in construction, Iron Sulfide Sand delivers controlled abrasion to create a textured base that enhances adhesion for subsequent coatings or overlays.

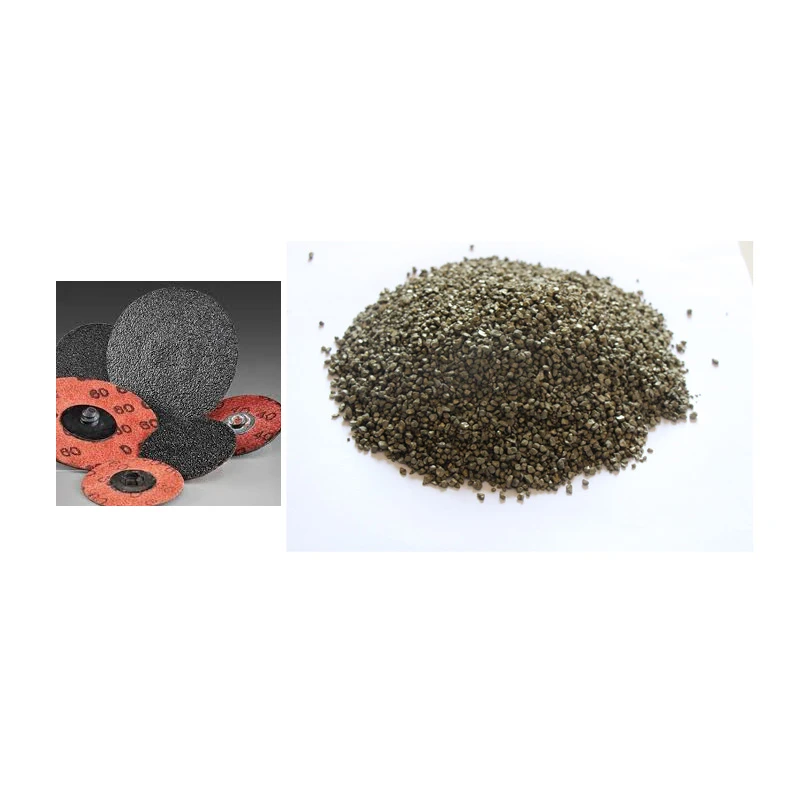

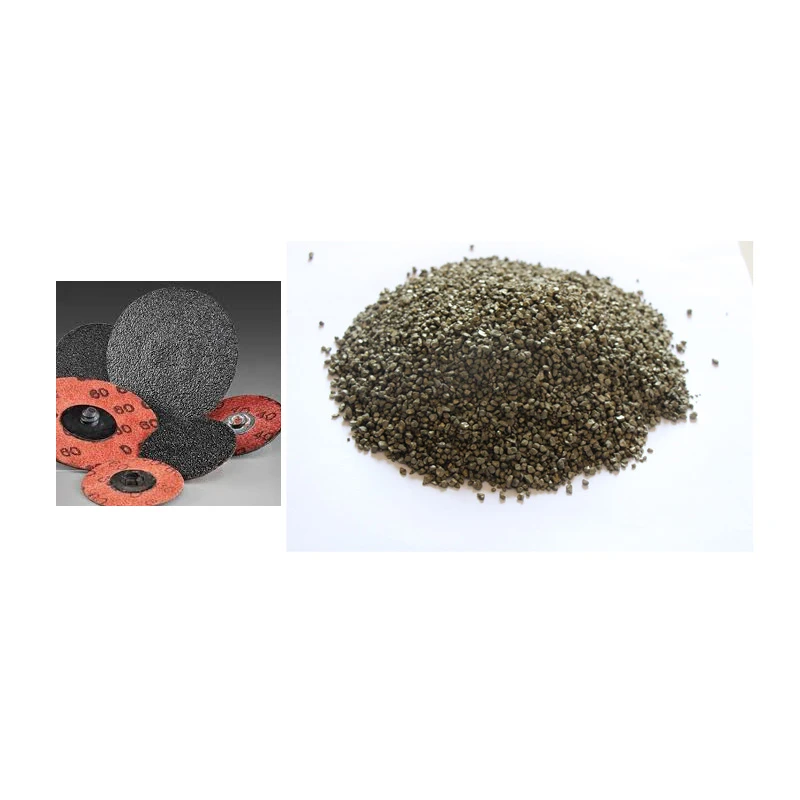

Iron Sulfide Sand Best For Abrasives High-Quality Effective Molds Premium Supply Deal

Iron Sulfide Sand for Abrasives, derived from high-quality iron sulfide (FeS₂) mineral, is a specialized abrasive material designed to deliver exceptional performance in various surface treatment and finishing applications. With its unique combination of hardness, durability, and abrasive efficiency, this product stands out as a reliable choice for industries seeking consistent results in cleaning, deburring, and texturing surfaces.

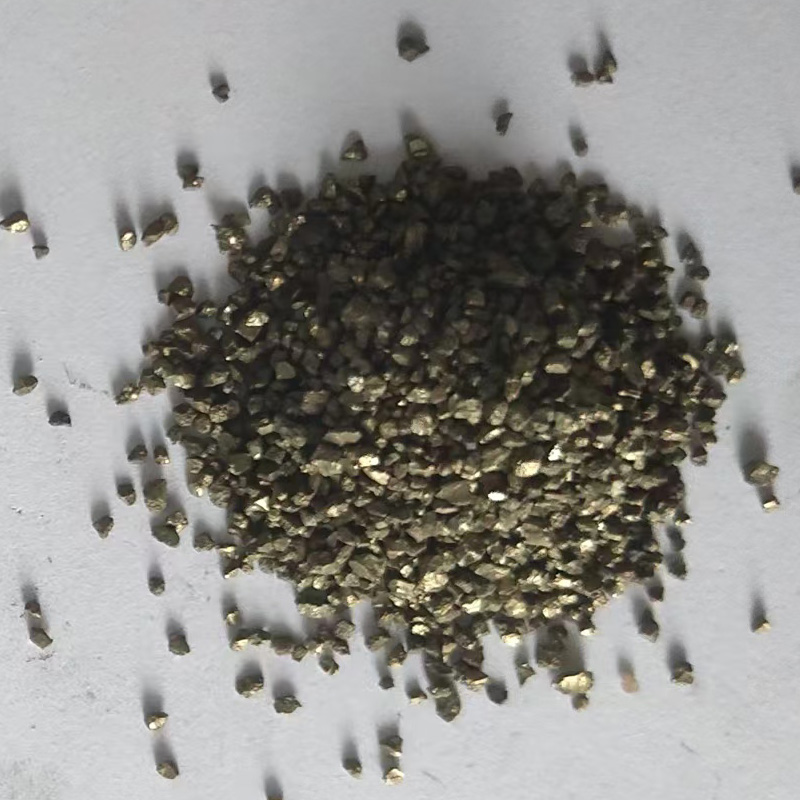

- Superior Hardness: Boasting a Mohs hardness of 6–6.5, our iron sulfide sand offers excellent cutting power, making it highly effective for removing rust, paint, and scale from metal surfaces.

- Uniform Particle Size: Available in precisely controlled particle sizes (ranging from 16 mesh to 120 mesh), ensuring consistent abrasive action and reducing the risk of uneven surface finishes.

- High Durability: Resistant to fragmentation during use, the sand maintains its abrasive properties for longer periods, minimizing material waste and lowering operational costs.

- Cost-Effective: Compared to traditional abrasives like aluminum oxide or silicon carbide, iron sulfide sand provides a more economical solution without compromising on performance.

- Low Dust Generation: Our advanced processing techniques reduce dust formation during application, improving workplace safety and reducing the need for extensive dust collection systems.

| Parameter | Details |

| Chemical Composition | FeS₂ (Iron Sulfide) |

| Mohs Hardness | 6–6.5 |

| Particle Size Range | 16 mesh, 24 mesh, 36 mesh, 46 mesh, 60 mesh, 80 mesh, 120 mesh (custom sizes available) |

| Bulk Density | 2.8–3.2 g/cm³ |

| Moisture Content | ≤ 0.5% |

| Acid Insolubles | ≤ 3% |

| Color | Brass-yellow to gold |

- Metal Surface Preparation: Ideal for cleaning and preparing metal surfaces before painting, coating, or welding. Effectively removes rust, old paint, and mill scale, ensuring strong adhesion of subsequent finishes.

- Foundry Industry: Used in sandblasting operations to clean castings, removing excess material and improving surface smoothness.

- Construction: Suitable for abrasive blasting of concrete surfaces to remove coatings, create a textured finish, or prepare for resurfacing.

- Automotive Refinishing: Helps in restoring automotive parts by removing corrosion and old paint, preparing them for repair or repainting.

- Aerospace Maintenance: Used for precision cleaning of aerospace components, ensuring they meet strict industry standards for performance and safety.

- Storage: Store in a dry, well-ventilated area away from direct sunlight and moisture. Keep bags sealed when not in use to maintain product quality.

- Handling: Use appropriate personal protective equipment (PPE) such as gloves, goggles, and dust masks when handling the product. Avoid inhalation of dust and minimize skin contact.

- Quality Assurance: Our iron sulfide sand undergoes rigorous testing at every stage of production to ensure it meets the highest industry standards. We are ISO 9001 certified, guaranteeing consistent quality.

- Custom Solutions: We understand that different applications require specific abrasive properties. That’s why we offer custom particle sizes and packaging to meet your unique needs.

- Expert Support: Our team of technical experts is available to provide guidance on product selection, application techniques, and troubleshooting, ensuring you get the most out of our abrasive sand.

- Sustainable Practices: We are committed to environmentally responsible mining and processing, minimizing our impact on the environment while delivering high-quality products.

Ready to enhance your surface treatment processes with our Iron Sulfide Sand For Abrasives? Get in touch with us today for a quote or to learn more about our products.

- Email: bnsales01@tlbainuo.com

- Whatapp/Wechat/phone:+86 18006417081

- Website: https://www.tlbncn.com/

- Address:No. 402, Building 9, No. 2899, North Section, Tongdu Avenue, Xihu Town, Tongguan District, Tongling City, Anhui Province

-

Leave a message!

Leave a message!

related products

related products