How to Choose High-Quality Pyrite Powder? Key Specifications Explained

Release time: 2025-11-07

Table of Contents

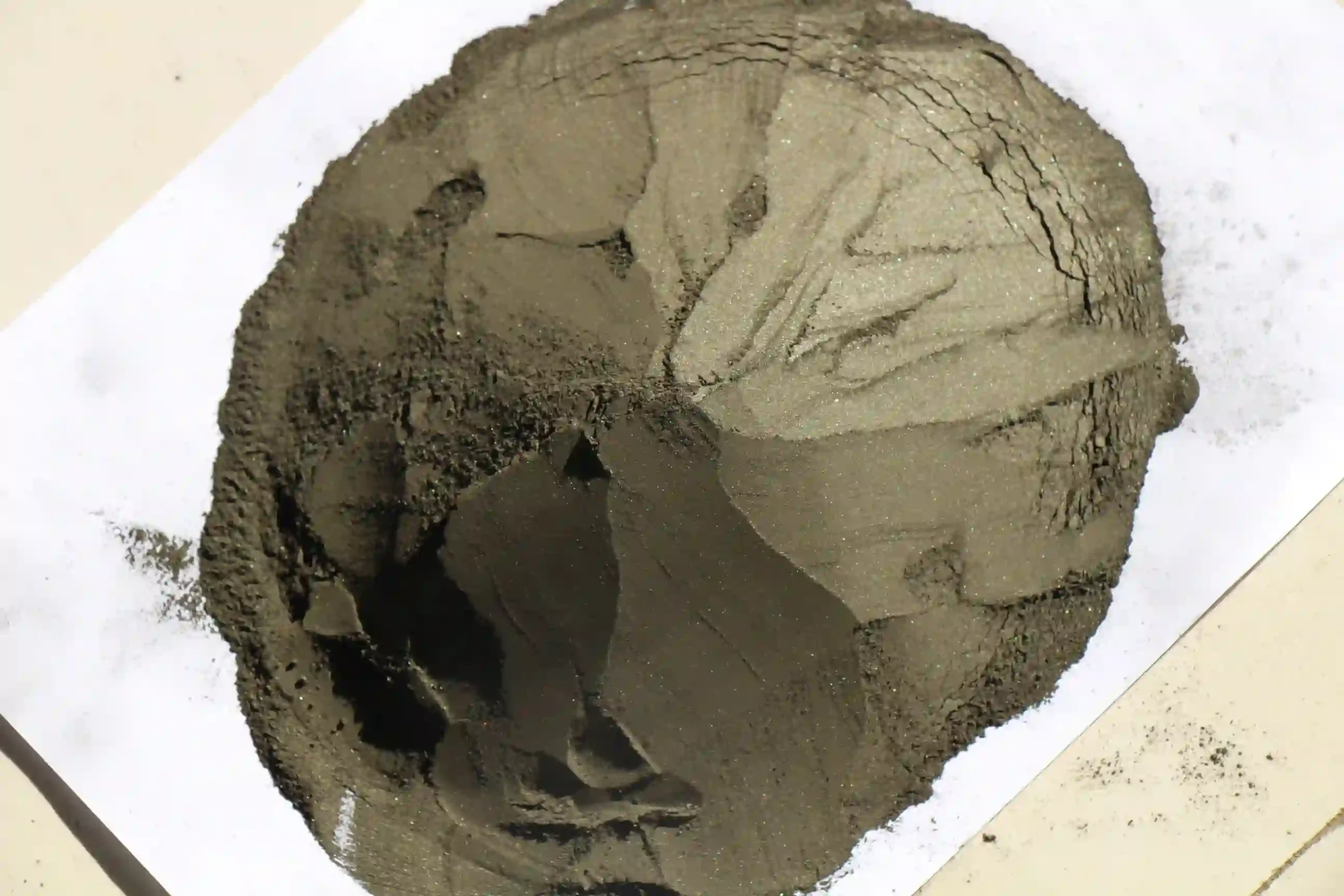

Pyrite powder, also known as iron pyrite powder, is widely used in friction materials, metallurgy, casting, chemical production, and even in the emerging lithium battery industry. With the growing demand in industrial applications, choosing high-quality pyrite powder becomes a key factor for product performance and production stability. For buyers, especially in bulk sourcing, understanding technical specifications, purity, and mesh size can help avoid quality issues and reduce procurement risk.

Bainuo will explain how to select suitable high-purity pyrite powder, what technical indicators matter most, and how to evaluate a reliable supplier.

Check Chemical Composition (Fe & S Content)

One of the most important parameters when purchasing pyrite powder is its chemical composition. The Fe (iron) content usually ranges from Fe40%–Fe50%, and sulfur content directly affects its efficiency in applications such as sulfur source and metallurgical processing. For friction materials or battery applications, high-sulfur and high-purity pyrite powder is often preferred.

A trustworthy supplier should provide COA, MSDS, and laboratory test results to guarantee stable chemical composition. If detailed composition data is not available, it may indicate inconsistent quality.

Verify Particle Size & Mesh Requirements

Different industries require different mesh sizes. Common specifications include pyrite powder 200 mesh, 300 mesh, and 325 mesh. Finer and more uniform powder usually provides better dispersion and surface contact, especially in friction materials and catalytic applications.

200 mesh pyrite powder – suitable for metallurgy and chemical industry

300-325 mesh fine pyrite powder – preferred for brake pads, grinding wheels, casting additives

Micronized or ultra-fine pyrite powder – ideal for advanced applications such as battery materials

Before purchasing, confirm mesh tolerance, moisture rate, and impurity content with the supplier.

Purity & Impurities Level

Purity is a key indicator when evaluating premium grade pyrite powder. Lower impurities mean more stable performance in industrial production. Ask whether the supplier uses magnetic separation or flotation processes to ensure low contamination from quartz, lead, copper, or organic materials.

If your production requires high performance, choose high-grade pyrite powder with consistent purity and low impurity content.

Packaging, Storage & Transportation

Moisture absorption and oxidation may lead to quality degradation. Therefore, packaging and logistics should not be ignored. Good suppliers usually use inner plastic waterproof bags + outer woven packaging to prevent moisture during storage and transport.

For bulk orders, check if pallet packaging or customized packing is available to reduce damage and leakage risk.

Work With a Professional Supplier

Choosing the right supplier is as important as the product itself. A reliable pyrite powder manufacturer or supplier should provide:

Stable long-term supply capacity

Technical documents (COA/MSDS)

Custom mesh size and sulfur content on request

Sample testing before bulk purchase

Export experience and quality control system

Working with an experienced factory helps ensure stable quality and reduces procurement time.

Conclusion

Selecting high-quality pyrite powder requires focusing on chemical composition, mesh size, purity, packaging, and supplier reliability. Whether for friction materials, metallurgy, casting, or battery production, understanding these specifications will help you choose the most suitable product and optimize your production cost.

If you are looking for high-purity pyrite powder or bulk purchase solutions, we can provide customized specifications, stable supply, and technical support. Contact us to get a sample or quotation.