Applications and Advantages of Pyrite Powder in Metal Extraction

Release time: 2025-09-27

Pyrite powder, as an important mineral raw material, has been widely used in various industrial fields in recent years. In particular, it demonstrates unique advantages in metal extraction, not only improving extraction efficiency but also reducing production costs. Tongling Bainuo will provide a detailed introduction to the applications and advantages of pyrite powder in metal extraction to help you better understand the value of this raw material.

Basic Properties of Pyrite Powder

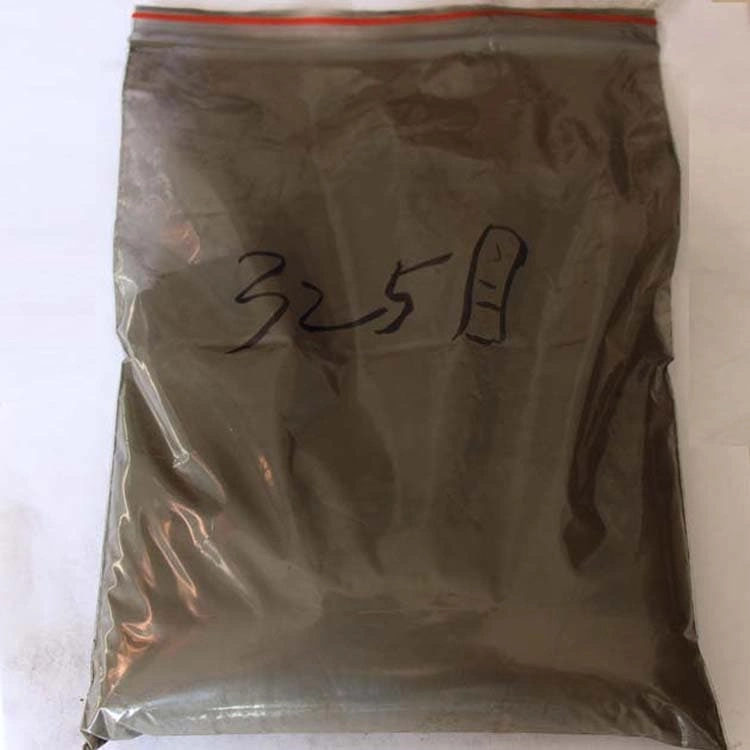

Pyrite powder, primarily composed of iron disulfide (FeS₂), is a common sulfide mineral. Its fine particles and high chemical reactivity make it highly reactive, allowing it to react strongly with other substances and play a vital role in the metal extraction process. In particular, pyrite powder can effectively facilitate the separation and purification of metals in the smelting of copper, lead, and zinc.

Applications of Pyrite Powder in Metal Extraction

Copper Extraction

In copper extraction, pyrite powder is often used as a sulfiding agent. By reacting pyrite powder with copper ore, copper separation and extraction can be facilitated. Pyrite powder also effectively removes impurities from the ore, facilitating the copper purification process.

Lead and Zinc Extraction

Pyrite powder also plays a vital role in lead and zinc extraction. By reacting with the sulfur in the lead or zinc ore, pyrite powder helps form easily separable lead or zinc sulfide. This process significantly improves extraction efficiency and reduces energy consumption.

Applications in Gold Extraction

Pyrite powder also plays a significant role in gold extraction. Pyrite powder reacts with other metals in the ore, making gold extraction more efficient. During the gold smelting process, pyrite powder not only aids in metal separation but also increases ore recovery.

Advantages of Pyrite Powder in Metal Extraction

Improving Extraction Efficiency

Pyrite powder accelerates the metal separation process and improves metal extraction efficiency. During the smelting process, pyrite powder, as a highly reactive raw material, can accelerate the reaction between metals in the ore and other substances, reducing smelting time and thereby improving overall production efficiency.

Reducing Production Costs

Using pyrite powder as a sulfiding agent in the metal extraction process can effectively reduce production costs. Compared with other traditional sulfiding agents, pyrite powder is less expensive and its high reactivity reduces the use of other high-cost materials. By rationally utilizing industrial-grade pyrite powder, companies can reduce raw material and energy consumption in production.

Environmentally Friendly

The use of pyrite powder has a minimal impact on the environment. Compared with some chemical reagents, pyrite powder is more widely available, and its production process is less polluting. Therefore, the use of pyrite powder in metal extraction aligns with the trend of green development in modern industry.

Enhancing Metal Purity

During the metal extraction process, the addition of pyrite powder helps remove impurities from the ore and improve the purity of the metal. For example, in copper extraction, pyrite powder not only helps separate the copper but also effectively removes impurities, improving the quality of the final metal.

Market Prospects of Pyrite Powder

With increasingly stringent environmental protection requirements and the growing demand for metal resources, pyrite powder holds broad application prospects in metal extraction. By utilizing pyrite powder scientifically and rationally, companies can achieve efficient resource utilization, reduce production costs, and promote sustainable development.

Conclusion

In summary, as an important mineral raw material, pyrite powder offers significant advantages in metal extraction. From improving extraction efficiency to reducing production costs, and increasing metal purity, pyrite powder plays an indispensable role. With the continuous growth of market demand, the application prospects of pyrite powder will continue to expand, making it an indispensable part of the modern metallurgical industry.

Tongling Bainuo is a professional pyrite powder supplier specializing in the production and development of iron sulfide, mica iron oxide, sulfur-containing media, titanium alloy sand, and copper removal media. If you have any questions about our products, please feel free to contact us!